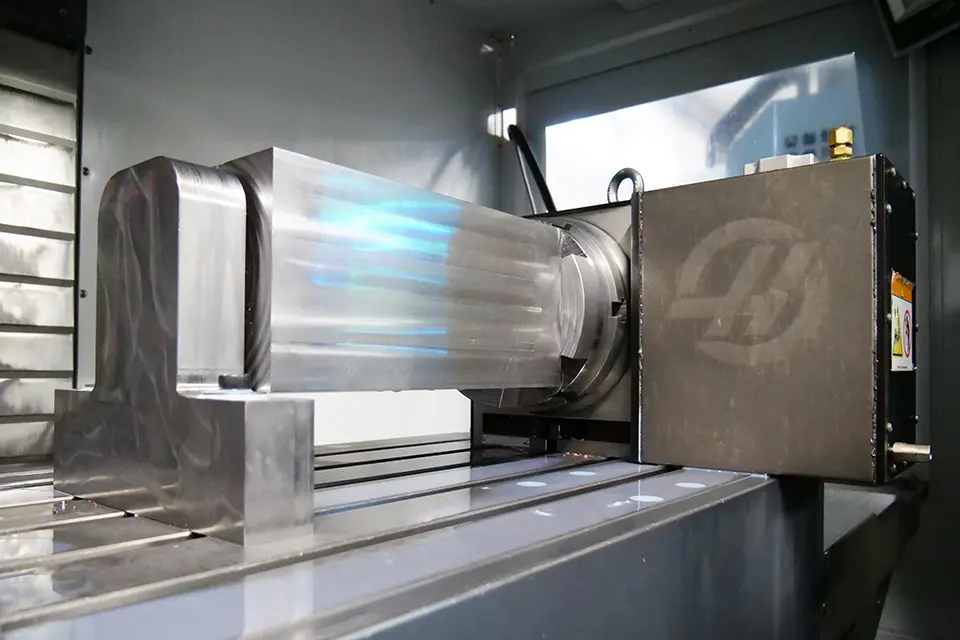

CNC milling

DWJ Narzędziownia CNC

You can watch us:

What is CNC milling?

At the outset, it is worth finding out what CNC milling is.

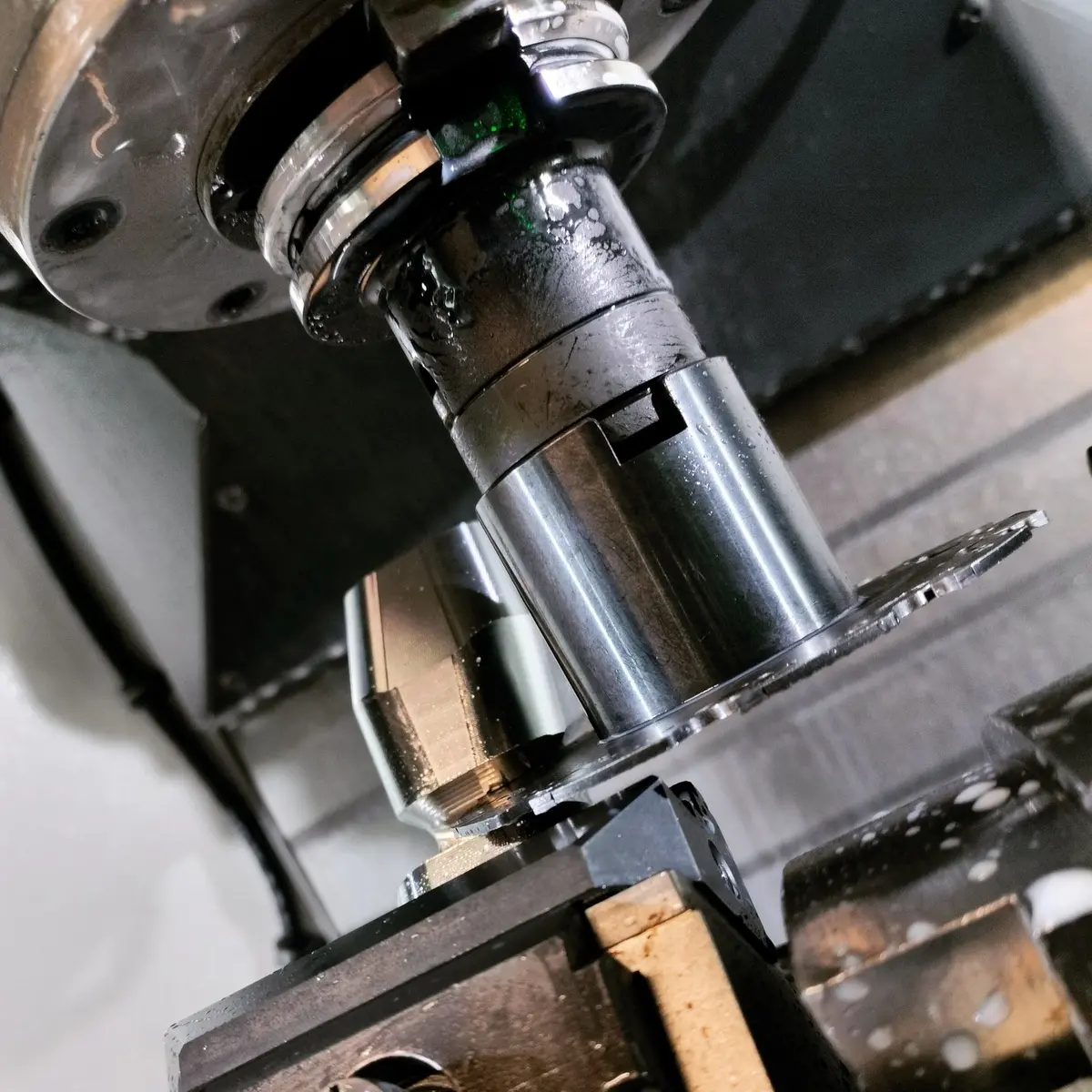

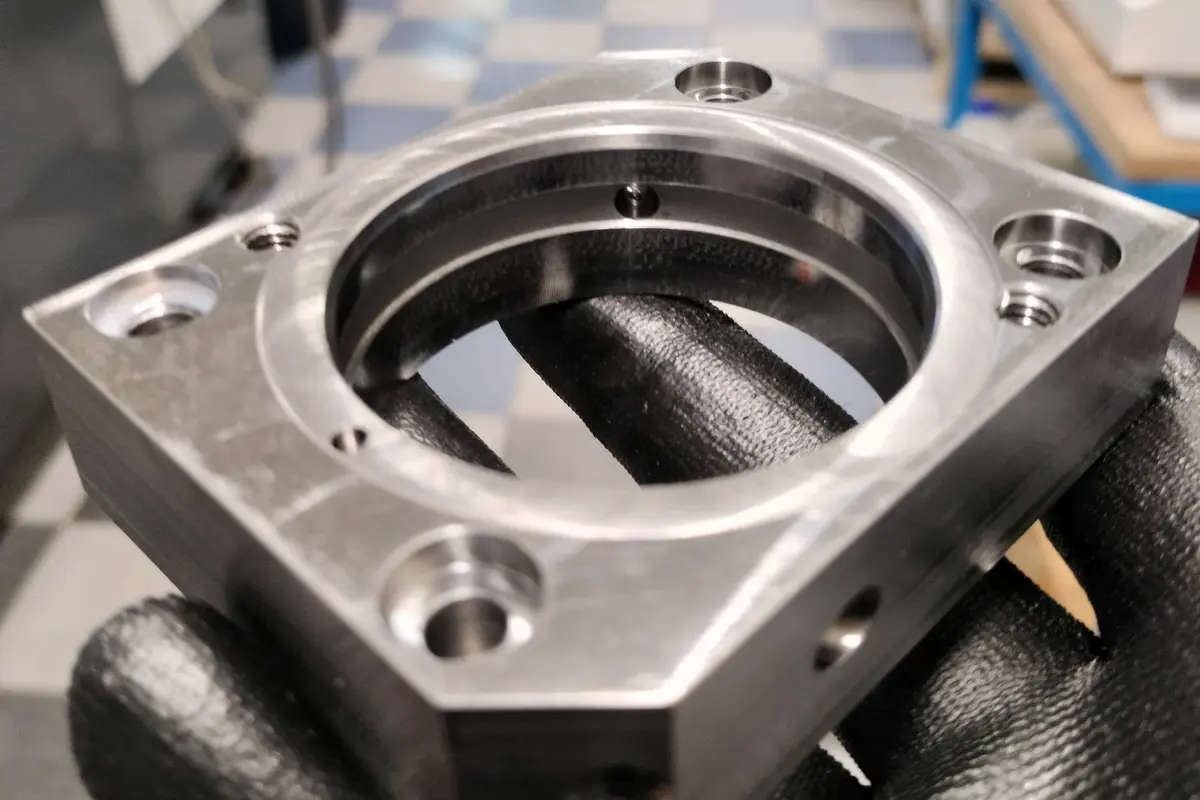

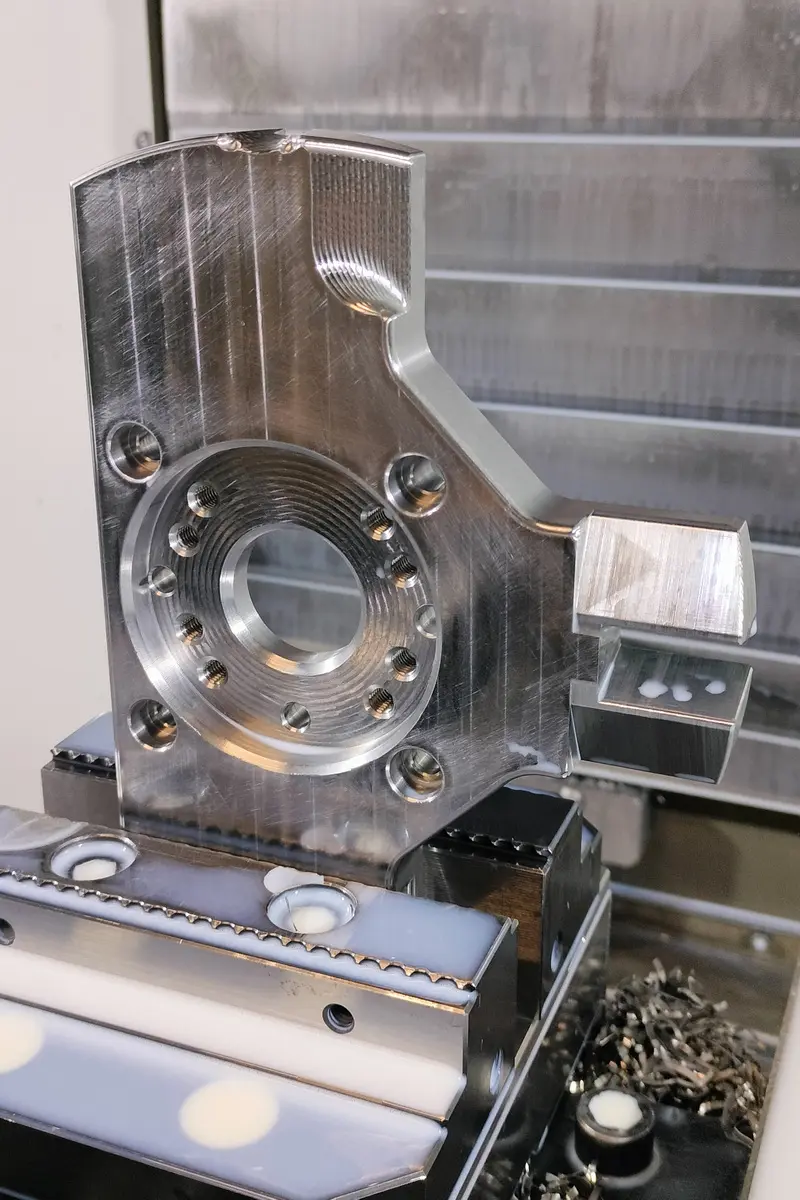

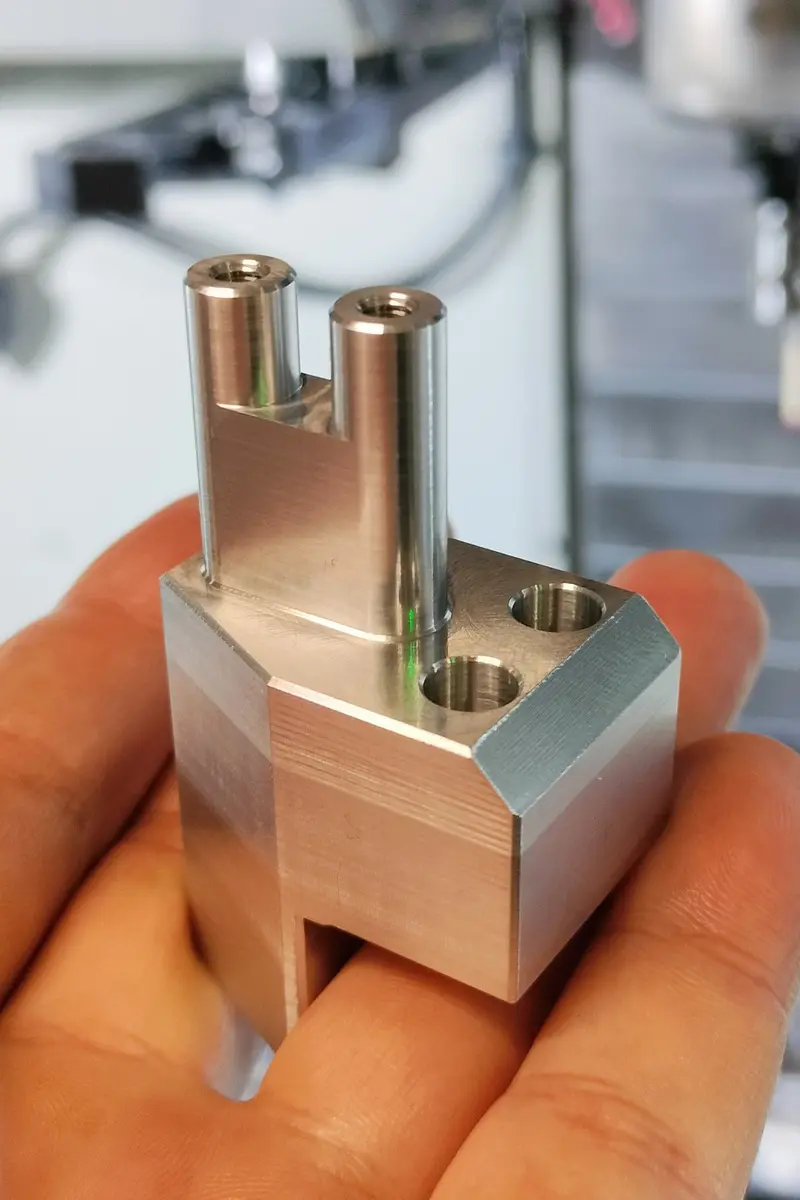

It is one of the chip machining methods where a specific shape is created by gradually removing the excess material. The result of this operation is the obtained shape, dimension and surface roughness. The most commonly used tools for milling are cutters, milling heads with different geometries. CNC milling takes place on milling centres or milling machines. Due to the versatility of this machining method, we can achieve literally any shape.

In contrast to lathes, the machining technique is completely different. In turning, the turning motion is performed by the workpiece and the tool is fixed to the turned part, whereas in a milling machine, the turning motion is performed by the tool and the workpiece is stationary. This is one of the most important differences between a lathe and a milling machine. With a milling machine, we are dealing with intermittent machining, as the blades of e.g. the milling cutter repeatedly penetrate the material, which results in a completely different chip formation compared to turning. It is a free-flowing chip and, in the case of a lathe, often a ribbon-like chip. This is influenced by the machining method.

CNC milling, advantages:

The most important advantages of CNC milling are:

- high accuracy machining,

- possibility of 1:1 mapping of the design,

- highly reproducible production with a defined precision,

- efficient machining,

- material saving,

- flexible machining

- possibility of machining very complex shapes,

- machining of various materials (e.g. aluminium milling),

- batch production, mass production without major human

- intervention,

- economy of machine operation.

DWJ