CNC machining

DWJ Narzędziownia CNC

You can watch us:

Advantages of CNC

CNC machining is carried out to produce precise and reproducible parts in metals, plastics or wood. Efficiency, speed and lower production costs are what CNC machine tools are all about

CNC machining or milling, CNC turning is a cost-effective and productive service used in virtually every industry (from medicine to agricultural machinery parts, robotics, automation, automotive and many others) .

As you can easily guess , the use of CNC machine tools has led to an increase in work efficiency. CNC machining of metals, plastics or wood is now considerably cheaper and has significantly sped up production. To make CNC machine tools even more efficient, a fully-automated robot can be added to serve as a human factor when, for example, replacing workpieces.

In the past, work was based on human error . The entire machining process consisted of manually adjusting the machine knobs and controlling it with levers or buttons. This resulted in enormous losses, as it is not difficult to make a mistake with such high precision. Precision is therefore the first buzzword for the new machining technology.

DWJ

CNC programmer

Let’s start by saying that to become a CNC programmer , you don’t have to be outstandingly skilled in IT, because in this case CNC programming is slightly different from standard IT programming.So what is CNC programming, what is the job of a CNC programmer, what programmes are most commonly used?

CNC programming is nothing more than the creation of a programme in a given language and format to control the operation of a machine. It should be done in a way that produces NC code in the shortest possible time. There are two types of programmers , those who write programmes on the computer in CAM and those who write programmes manually on the machine. I personally prefer programming in CAM as in my case it is the most efficient.

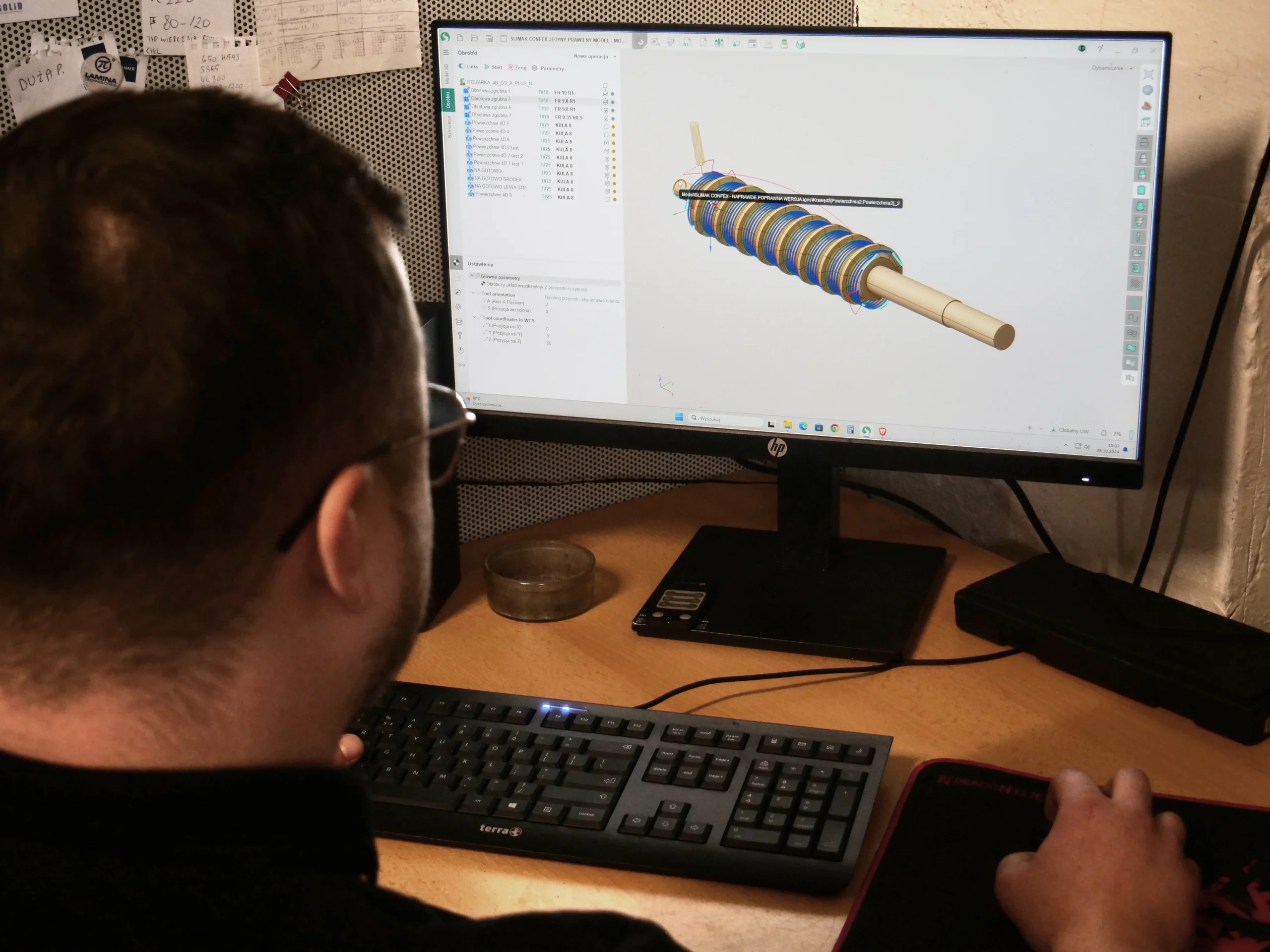

Writing a programme in CAM involves uploading a finished model previously made in CAD and then selecting a toolpath. There are various functions assigned to this, such as drilling, roughing, finishing, 2D contouring, 3D contouring, chamfering, countersinking, threading, planning, drilling, face cleaning and many others.

On-machine programming, colloquially known as “with the finger”, is based on cycles and manual entry of NC code . The cycles in this case are similar to those of CAM . Personally, I think it is a matter of getting used to which programming path the programmer chooses, but it is significantly influenced by the software on the CNC machine and the CAM programme.

As we are already on the subject of software and CAM programmes, I will mention the most popular ones:

– On machines these are Hidenhain, Fanuc, Sinumerik

– On the computer: SprutCam, SmartCam, Fusion360Cam

DWJ

CNC operator

CNC machining of various materials using numerical control machines (CNC machines) is widely used in various industries, and with the growing CNC industry there is an increasing demand for operators . What do you need to know if you are interested in working on CNC machines? What does a CNC operator do? What are the duties of a CNC operator? How much can you earn as a CNC operator?

Let’s start with what CNC machine tools are. In other words, they are specialised numerical control systems. This type of machine, controlled by a computer, is capable of performing various machining operations such as milling, turning, grinding, drilling, plasma burning and many others. The advantage of CNC numerical control machines is the ability to start serial production and the high quality of the manufactured parts.

The CNC operator is responsible for almost the entire production process. His/her duties include the selection of appropriate (tools, parameters), setting up the workpiece, supervising the process during machining, final measurement of the workpiece.

Many factors influence the earnings of a CNC operator. One of them is the area of duties that belong to him. If the operator’s job is only to push the green button and replace the piece in the machine then you cannot count on much. On the other hand, if the operator is self-sufficient, i.e. is able to write the programme himself, operate CAD/CAM, select tools and parameters, set the workpiece and measure the finished product, such an employee may earn a lot. In Poland, for the position of CNC operator, the median gross salary is 4840 PLN per month, but we know from our experience that the earnings range from 2800 PLN net to 8500 PLN net. CNC machining is carried out in order to obtain precise and repeatable elements from metals, plastics or wood.

DWJ

Technologist

In our company, technologists take care of the quotation request, determining the time needed for CNC machining. We undertake the execution of orders with material entrusted to us or ordered by us.

It is important that enquiries sent to us include specific features, i.e. material, quantity and completion date, or relevant technological documentation, which will facilitate and speed up the valuation process, avoiding unnecessary questions.

We try to respond quickly because we value our time, but above all the time of the client. We are always happy to advise and help when the customer has questions. We take an individual approach to each enquiry, the price usually depends on the quantity required and the deadline for us to produce the details.

On receipt of an order, the technologists proceed to develop the processing technology, which is then transferred to the workshop. If necessary, they are happy to help solve problems and share their knowledge.

The technologists are also competent to draw 3D models in modern CAD software, at the customer’s request after receiving complete drawing documentation.

DWJ

3D modelling

A special computer programme that is equipped with tools and groups of basic geometric figures allows us to create and edit three-dimensional solids. 3D models are used by designers and technologists in various fields of industry.

They are used in the initial phases of projects to create prototypes or to recreate worn-out components. At the solid modelling stage, it is possible to detect design flaws and correct them immediately before the stage of making components on CNC machines. Our company DWJ Narzędziownia CNC deals with 3D solid modelling, thanks to which we create designs and jigs. Advanced technology, knowledge and many years of experience in the industry on the subject of modelling allow us to shorten the time and reduce potential costs of the order, as well as to refine the fit of the created elements. In almost all industries, 3D modelling is an essential tool at the start of the creation process.

DWJ