CNC turning

DWJ Narzędziownia CNC

You can watch us:

CNC turning – metal and plastic processing services.

At the outset, it is worth explaining what turning is?

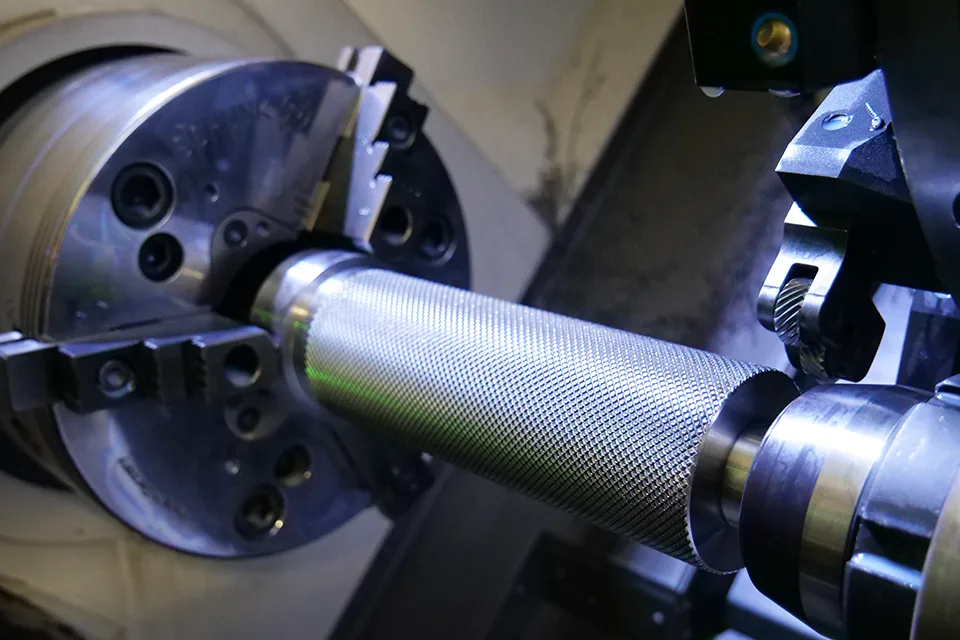

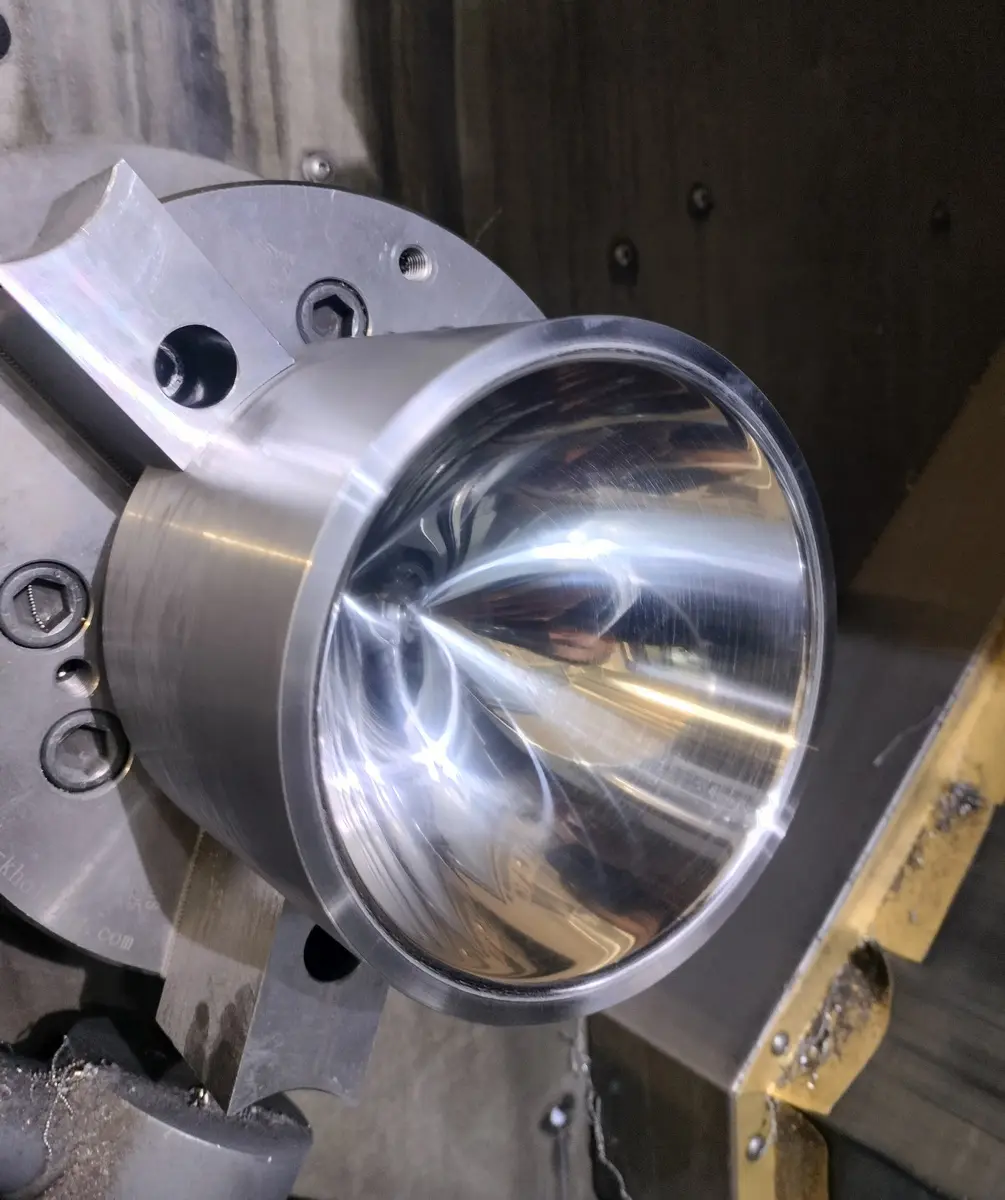

It is a type of chip machining used to machine the external, internal and face surfaces of shafts mounted in a lathe chuck on a lathe. The material in the chuck rotates about its axis and by applying the lathe knife to the shaft, the turning process takes place. That is, it involves separating a layer of material from the workpiece with the lathe knife, in order to obtain a specific shape and dimensions.

The first lathes were used in Egypt as early as the Bronze Age. Of course, they did not look like modern lathes. They were string lathes with reciprocating motion driven by a string through human labour.

CNC turning is a more accurate and highly repeatable form of machining than conventional turning. The machining principle is very similar, but the term “CNC” is key here. CNC (Computerised Numerical Control) gives us much greater possibilities for machining complex shapes, as a computer is responsible for all the movements of the machine tool. The physical involvement of a human being in the machining process is reduced in comparison to a conventional lathe, where a human being was responsible for every movement of the machine.

DWJ

CNC turning – precision

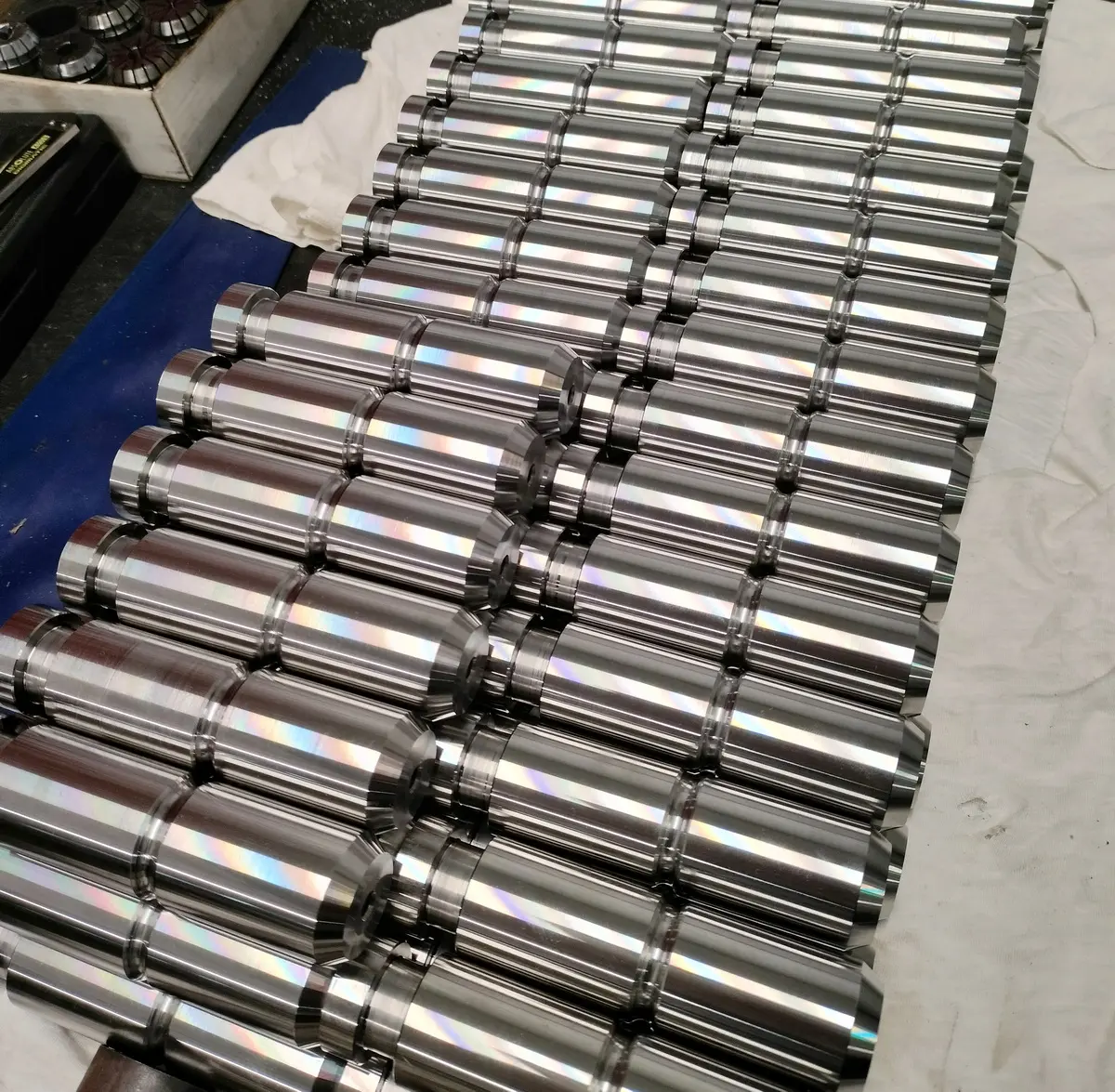

It is characterised by high repeatability and precision of the parts produced, as the machine is programmed to produce parts in a cyclic manner without interruption. Thanks to a good selection of the machine and its options, we can produce single parts as well as series in a short period of time and with high efficiency. Any dimensional corrections can be made in real time via the control panel. The programme for machining metal parts or parts made of other materials can be written from the user’s panel or by using a CAM computer programme. The use of appropriate tools and parameters allows us to turn parts with tight tolerances and demanding surface roughness in a very efficient manner.

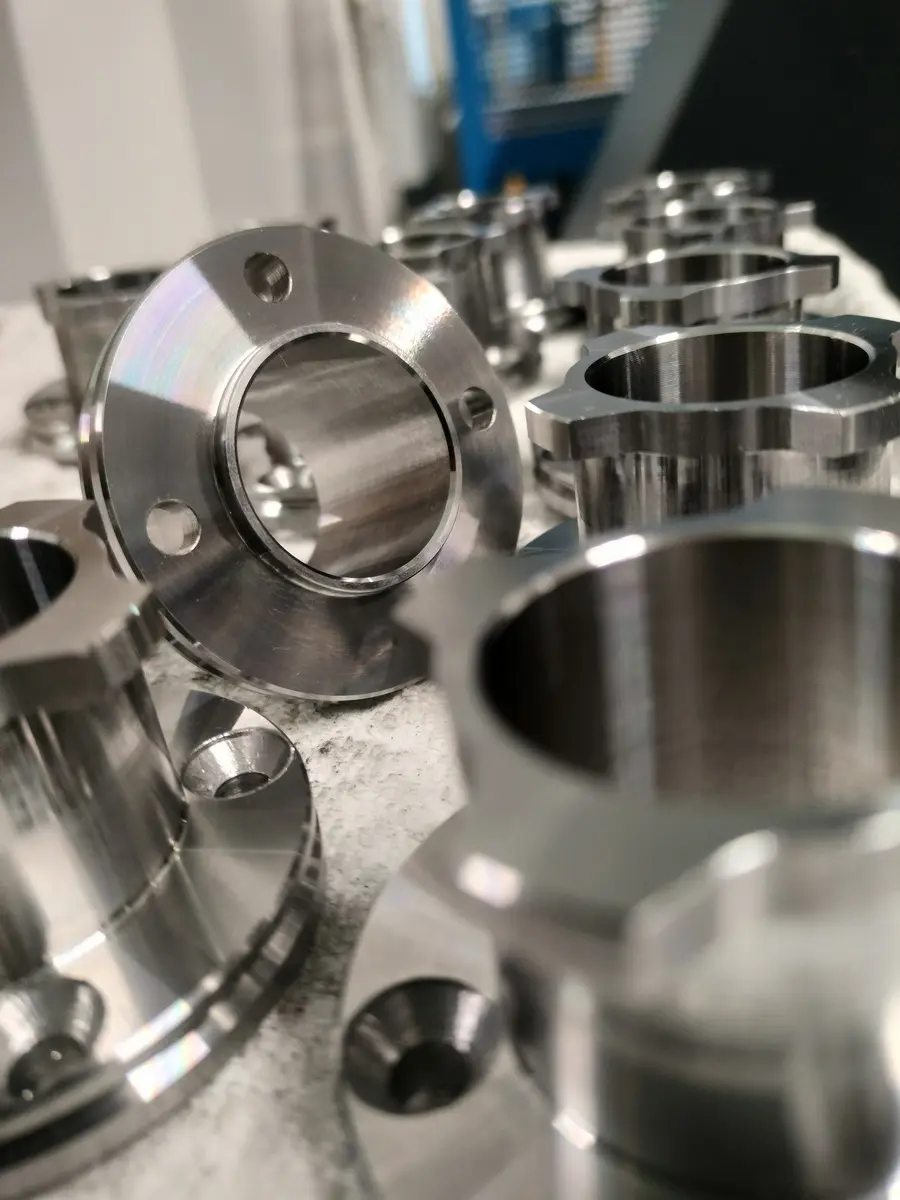

CNC turning in our company is a highly flexible process. Due to the high variety and availability of tools on the market, our range of cnc turning is very wide. Most often, we machine various types of metals and plastics.

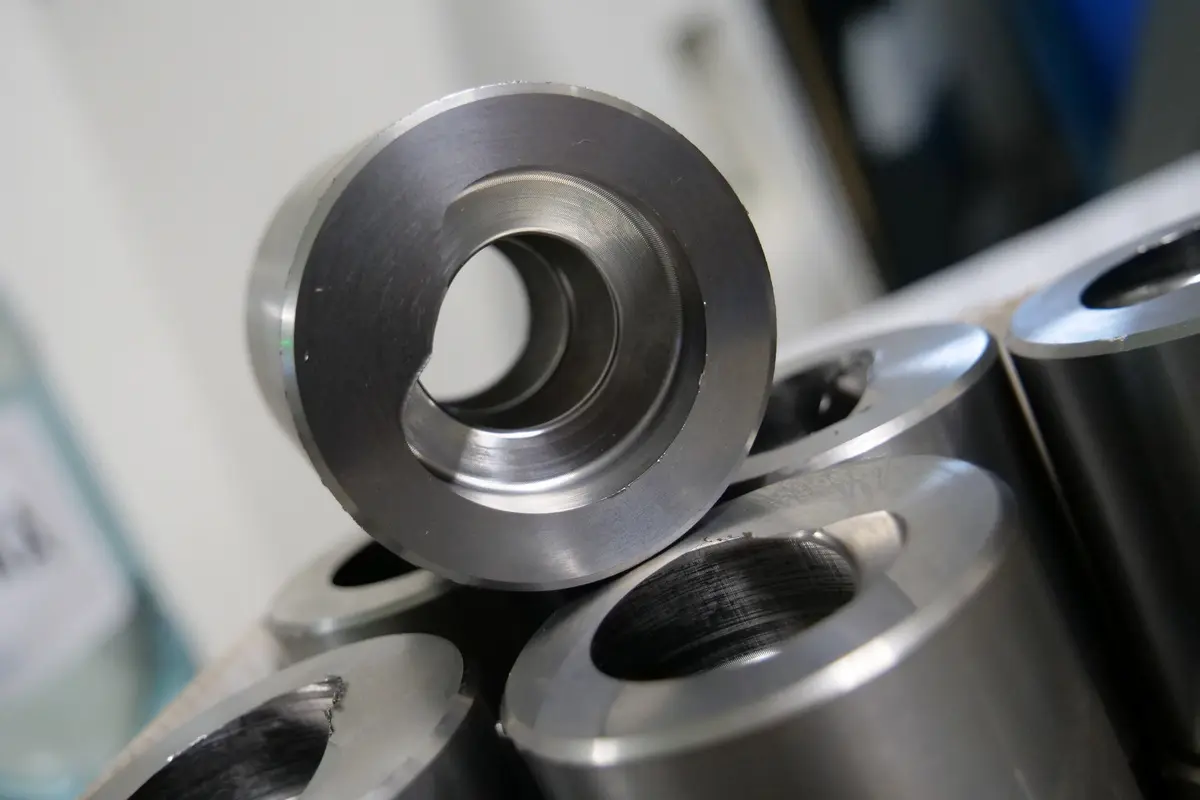

Products manufactured on CNC lathes.

The process of manufacturing parts on CNC lathes is very broad. Lathes are created for machining parts in the form of rotating solids. This can include various types of axles, shafts cylinders, bushings, threaded bolts, rings, cones, wheels, washers, pins and others.

The aforementioned components usually need additional operations such as milling. Nowadays, CNC lathes can be equipped with a milling option at purchase. This is being used increasingly by entrepreneurs to increase the versatility of the machine tool. The use of such an option shortens the production period, as the workpiece is produced on one machine.